Concrete Driveway Solutions for Lasting Performance

Concrete driveway installation enhances the functionality and curb appeal of residential and commercial properties. Properly installed concrete driveways offer durability, low maintenance, and a clean appearance, making them a popular choice for many property owners.

Initial land clearing and grading prepare the site for a stable foundation, ensuring proper drainage and longevity of the driveway.

Formwork shapes the driveway outline, followed by pouring and spreading concrete to create a smooth, level surface.

Finishing techniques such as troweling and texturing provide a durable, slip-resistant surface.

The process of installing a concrete driveway typically involves several key steps. Land preparation and grading ensure proper drainage and a solid base. Forming and pouring concrete shape the driveway, followed by finishing to achieve a smooth and durable surface. The entire installation can take several days, depending on the size and complexity of the project.

Residential installations focus on enhancing curb appeal and providing a durable surface for everyday use.

Commercial projects require larger-scale installations with emphasis on durability and load-bearing capacity.

Most concrete driveway installations are completed within a few days, with curing times influencing the final readiness.

Concrete driveways offer long-lasting performance with minimal upkeep, making them a cost-effective choice.

A smooth, clean surface that enhances property aesthetics.

Detailed edging provides a finished look and helps prevent cracks.

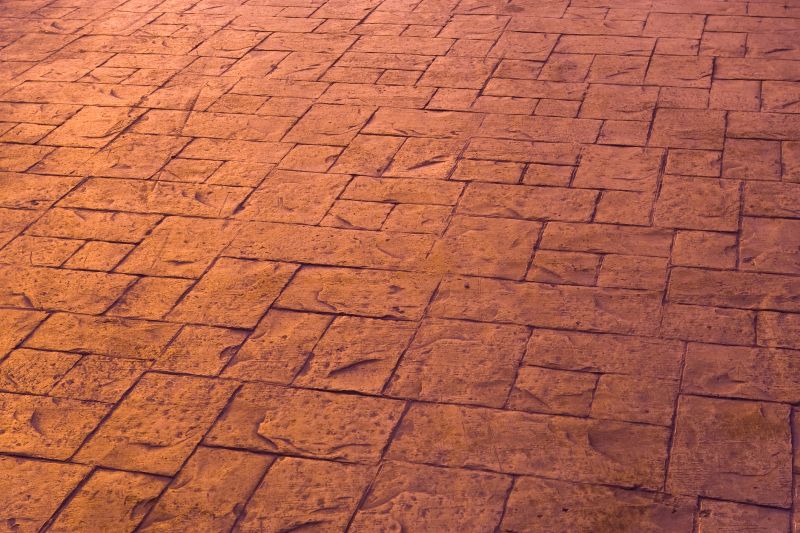

Additional images showcase the variety of finished concrete driveways, highlighting different styles and textures suitable for various property types.

Sleek and minimalist design suited for contemporary properties.

Decorative patterns and textures add visual interest and customization options.

Getting a concrete driveway installed involves careful planning and execution to ensure a durable, attractive result. Property owners can expect a professional process that includes site preparation, forming, pouring, finishing, and curing. Proper installation extends the lifespan and maintains appearance over time.

| Aspect | Details |

|---|---|

| Preparation Time | Typically a few days, depending on site conditions |

| Installation Duration | Usually completed within 2-4 days |

| Curing Period | Approximately 7 days for full strength |

| Suitable for | Residential and commercial properties |

| Maintenance | Minimal, including sealing and cleaning |

| Cost Factors | Size, design complexity, and site conditions |

| Lifespan | Decades with proper care |

| Design Options | Plain, stamped, colored, textured |